Oceaneering - AGVs for Automated Logistics

Embedded Product

Oceaneering AGV systems provide automated material handling solutions, tackling complex industrial and logistical challenges. Their autonomous vehicles streamline workflows in manufacturing and warehousing, enhancing efficiency and safety. These adaptable systems optimize material flow, reduce operational costs, and improve overall productivity in dynamic environments. Leveraging advanced navigation and control software, they facilitate seamless integration into modern, data-driven operations.

My time at Oceaneering AGV systems was a deep dive into the transformative power of automation within complex industrial and logistical landscapes. I was at the forefront of developing and deploying cutting-edge Automated Guided Vehicle (AGV) applications, crafting both the intelligent vehicle software and the overarching supervisor systems that orchestrate their movements. Beyond the code, my role involved nurturing strong client relationships, ensuring project effectiveness, and consistently delivering solutions that met demanding timelines. I also actively contributed technological insights, pushing the boundaries of our product's capabilities.

Witnessing the tangible impact of our work was incredibly rewarding. For Philip Morris Italy, I contributed to the successful completion of a landmark ~6 M€ project in 2018, deploying a sophisticated fleet of 34 cooperating AGVs navigating a network of approximately 1600 active pickup and drop-off points. This project showcased the potential of large-scale autonomous material handling to revolutionize intralogistics. Similarly, the ~2 M€ project for Tesla NL in 2015 involved the deployment of 33 AGVs operating across four independent loops with 10 critical points of operation, demonstrating the adaptability of our solutions to diverse manufacturing environments.

Beyond the technical intricacies, I honed crucial skills in managing customer expectations and navigating change requests, ensuring project success even amidst evolving needs. My daily responsibilities included meticulous priority scheduling, proactive escalation management, and fostering a motivated and effective team. Recognizing the power of agile methodologies, I obtained Scrum Master certification and championed its adoption, leading to improved effort tracking, enhanced time management, and greater transparency across the department. My commitment to continuous improvement extended beyond project delivery; I actively participated in the Change Management Task Force, collaborating with top management and colleagues to drive a company-wide transformation focused on elevating quality, performance, revenue, and fostering a more positive and productive work environment.

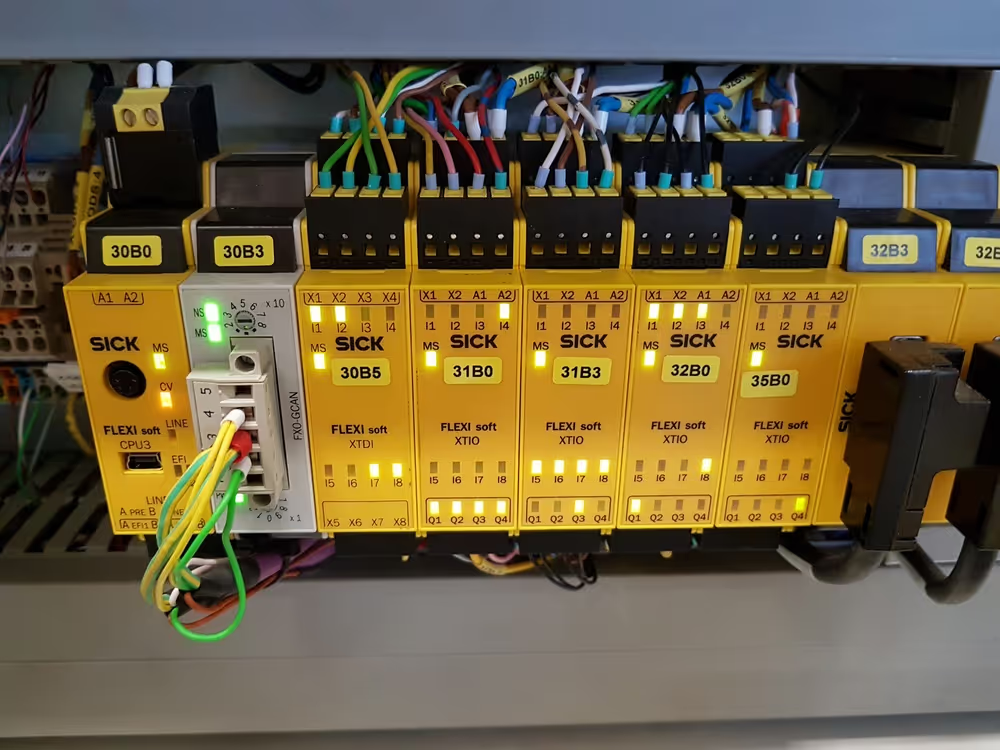

My toolkit at Oceaneering was built upon a foundation of robust technologies, including CentOS Unix systems, bash scripting for automation, and the core languages of C and C++ for developing critical AGV functionalities. I was proficient in utilizing build systems like makefiles and integrated development environments such as Netbeans and Eclipse, complemented by debugging and analysis tools like GDB and Valgrind. Version control was managed through SVN, and collaborative knowledge sharing was facilitated through MediaWiki. Troubleshooting network communication often involved the use of Wireshark, while interaction with industrial hardware relied on Beckhoff PLCs and custom-built distributed applications. This comprehensive experience has equipped me with a unique blend of technical expertise and strategic understanding to tackle the evolving challenges of industrial automation and logistics.